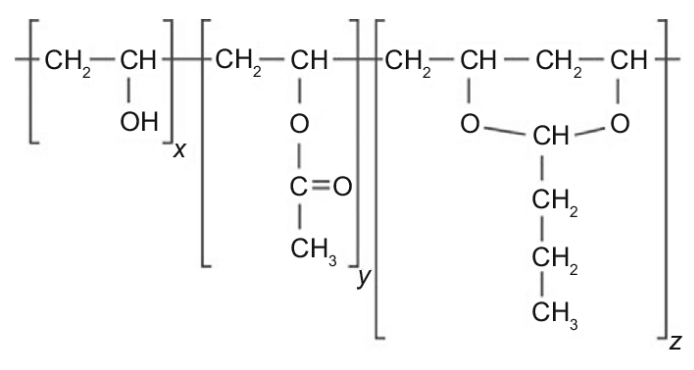

Polyvinyl Butyral Resin (PVB) resin, a versatile and highly adaptable material, has found its way into a myriad of applications across various industries. Its unique properties, such as transparency, durability, and adhesion, make it an indispensable component in modern manufacturing and technology.

PVB resin is widely used as an interlayer material in the production of safety glass. This type of glass boasts exceptional transparency and high impact resistance, making it ideal for applications in the aerospace and automotive sectors. Whether it’s for airplane windows or car windshields, PVB resin-based safety glass ensures both clarity and durability, providing an extra layer of protection in high-stakes environments.

In the realm of protective coatings, PVB resin plays a crucial role in manufacturing anti-corrosion and anti-rust paints. These coatings are known for their strong adhesion, excellent water resistance, and ability to withstand harsh weather conditions. Additionally, PVB resin is used to create metal primers and cold-resistant paints, ensuring that structures and machinery remain intact and functional even in extreme environments.

PVB resin is a key ingredient in the production of vibrant decorative films, which can serve as an alternative to traditional ceramic decals. These films are not only visually appealing but also highly durable. In the PVB resin industry, it is also used to create molding compounds that can replace metals like steel and lead. Furthermore, PVB resin-based adhesives are widely employed for bonding materials such as wood, ceramics, metals, plastics, leather, and laminated composites, showcasing its versatility.

The textile industry benefits from PVB resin in the form of fabric treatment agents and yarn tubes, which enhance the quality and durability of textiles. In the food industry, PVB resin is used to produce non-toxic packaging materials, ensuring the safety and integrity of food products. Its non-toxic nature makes it an ideal choice for packaging sensitive items like tea and cigarettes, where odor retention is a concern.

In the paper industry, PVB resin is utilized as a paper treatment agent, improving the strength and quality of paper products. Additionally, it is used to create anti-shrinkage agents, stiffening agents, and other waterproof materials, further expanding its utility in industrial applications.

PVB resin’s solubility in alcohols and non-toxic nature make it a preferred choice in the printing industry. It is compatible with various printing techniques, including flexography, gravure, letterpress, screen printing, and heat transfer printing. Its ability to produce odor-free prints makes it suitable for packaging sensitive items like tea and cigarettes. Moreover, its cationic properties allow it to adhere strongly to glass surfaces, making it particularly effective for glass decoration through screen printing.

From enhancing the safety of vehicles and aircraft to revolutionizing the printing and packaging industries, PVB (PVB SD-3 & PVB B-03HX) has proven to be a material of immense value. Its adaptability, combined with its eco-friendly and non-toxic characteristics, ensures that it will continue to play a pivotal role in shaping the future of technology and industry. As research and innovation progress, we can only expect to see even more groundbreaking applications of this remarkable material.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com